RO4003C 4-Layer 4.8mm Thick PCB with ENIG Finish and Countersunk Holes – Applications and Process Overview

1.Introduction of RO4003C

Rogers RO4003C materials are proprietary woven glass reinforced hydrocarbon/ceramics that combine the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. Available in various configurations using 1080 and 1674 glass fabric styles, RO4003C laminates deliver consistent dielectric constant (Dk) and low loss characteristics. They can be processed using standard epoxy/glass methods, offering a cost-effective alternative to traditional microwave laminates without requiring special through-hole treatments. RO4003C materials are non-brominated and not UL 94 V-0 rated. Their thermal expansion coefficient (CTE) closely matches that of copper, ensuring excellent dimensional stability and reliable plated through-hole integrity even under severe thermal conditions. With a Tg exceeding 280°C, RO4003C maintains stable expansion properties throughout circuit processing.

2.Key Features

Dielectric Constant: 3.38 ±0.05 at 10 GHz

Dissipation Factor: 0.0027 at 10 GHz, 0.0021 at 2.5 GHz

Thermal Coefficient of Dk: +40 ppm/°C

Thermal Conductivity: 0.71 W/m/°K

CTE: X: 11 ppm/°C, Y: 14 ppm/°C, Z: 46 ppm/°C

Moisture Absorption: 0.06%

3.Benefits

Ideal for multi-layer board (MLB) constructions

Compatible with FR-4 processing at lower cost

Suitable for performance-sensitive, high-volume applications

Competitively priced

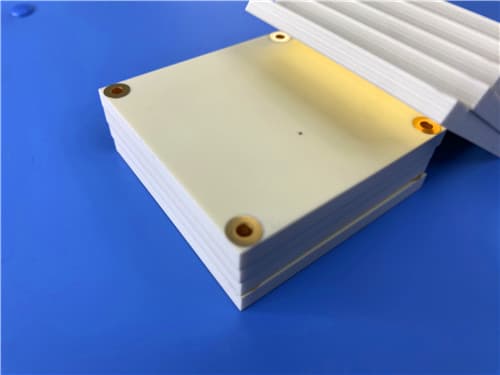

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | RO4003C |

| Layer Count | 5-layer |

| Board Dimensions | 60mm x 60mm (±0.15mm) |

| Minimum Trace/Space | 4/5 mils |

| Minimum Hole Size | 0.4mm |

| Blind Vias | No |

| Finished Board Thickness | 4.8mm |

| Finished Cu Weight (Inner/Outer) | 1oz (35μm) |

| Via Plating Thickness | 20 μm |

| Surface Finish | Electroless Nickel Immersion Gold (ENIG) |

| Top Silkscreen | Black |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Via Treatment | Filled with resin and capped on surface |

| Countersunk Holes | Conical, 90 degree |

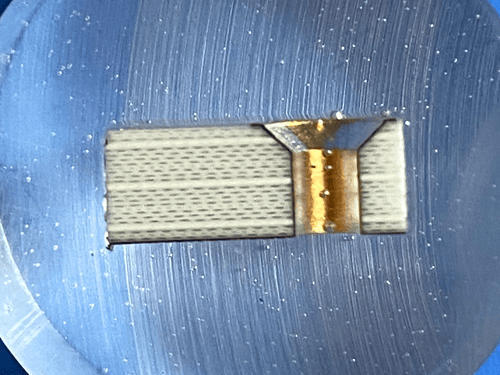

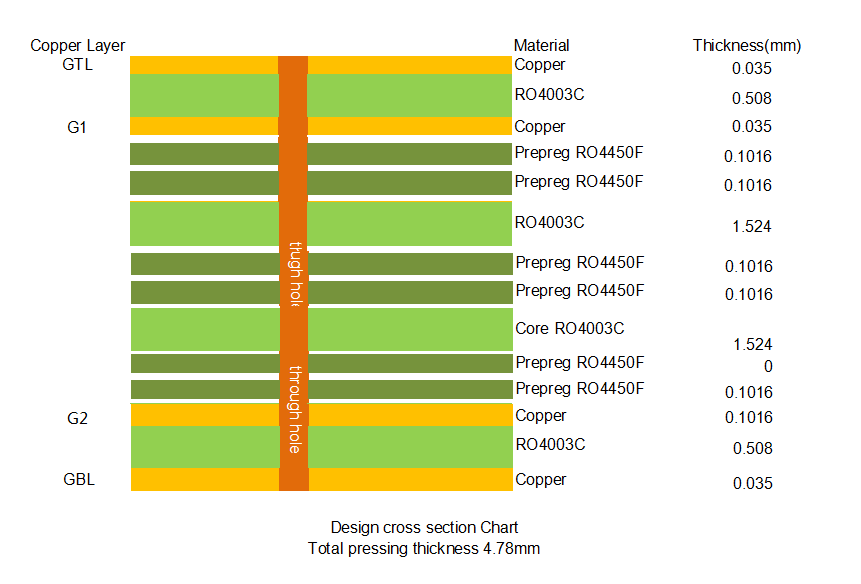

5.PCB Stackup (4-Layer Rigid Structure)

Copper_layer_1 - 35 μm

Rogers 4003C Core - 0.508 mm (20mil)

Copper_layer_2 - 35 μm

Prepreg RO4450F X 2 -0.204mm

Rogers 4003C Core - 1.524 mm (60mil)

Prepreg RO4450F X 2 -0.204mm

Rogers 4003C Core - 1.524 mm (60mil)

Prepreg RO4450F X 2 -0.204mm

Copper_layer_3 - 35 μm

Rogers 4003C Core - 0.508 mm (20mil)

Copper_layer_4 - 35 μm

6.PCB Statistics:

Components: 2

Total Pads: 7

Thru Hole Pads: 3

Top SMT Pads: 4

Bottom SMT Pads: 0

Vias: 5

Nets: 7

7.Typical Applications

Cellular Base Station Antennas and Power Amplifiers

RF Identification Tags

Automotive Radar and Sensors

LNBs for Direct Broadcast Satellites

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide